TAVI Glass table inspection system

Glass table-based inspection systems are perfectly suited for a fully automatic and non-destructive geometrical and defect inspection, thread inspection, and classification of serial parts for a broad range of applications. Since glass tables guarantee a very stable inspection and measurement process, these systems are recommended for sophisticated inspection tasks with tight tolerances or complex geometries.

Advantages in your production:

Technical information:

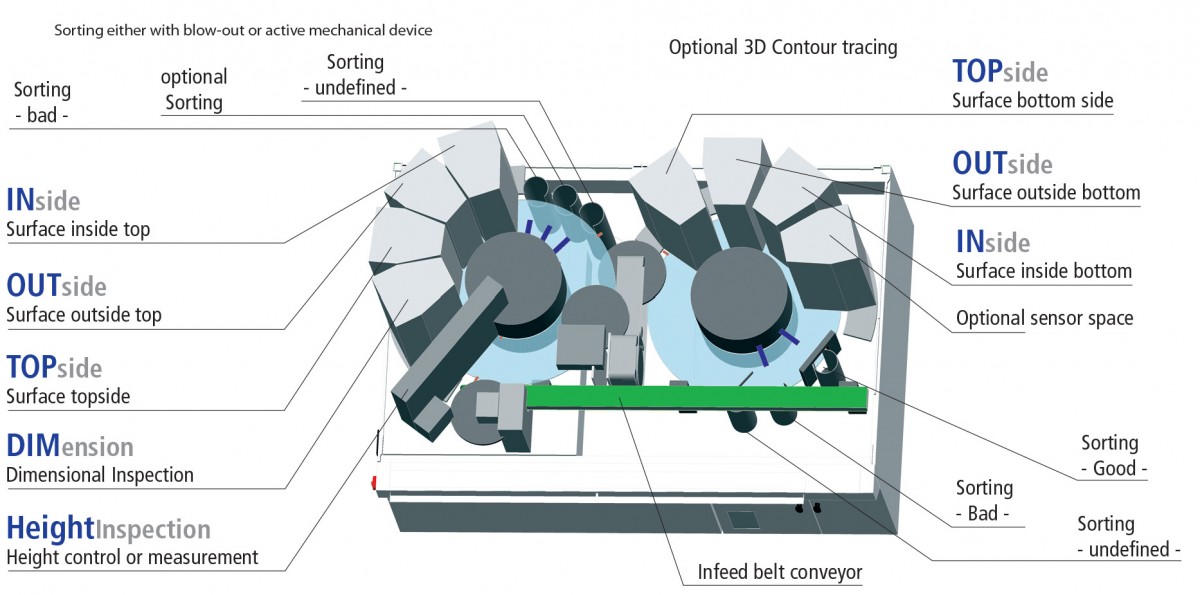

- Glass table system with / without component turning

- Dimensional accuracy inspection and defect inspection on front and side surfaces as well as lateral surface

- Equipped with 5 to 9 customised sensor units

- Throughput of up to 100,000 parts per hour (with TAVI.01-XL)

- Optimised for part size: OD 1mm - 80 mm (with TAVI.01-XL up to 120 mm)

- Measuring accuracy: from ±1μm

- Robust machine design with high-quality technological components

- Powerful multi-core processors for maximum inspection speeds

- Closed system design for maximum purity

- Glass disc calibration and temperature compensation for maximum measuring accuracy

How NELA inspection systems work:

Models of NELA glass table inspection systems:

TAVI.01 / TAVI.01-XL: inspection system with one glass table, recommended for parts which don’t have to be turned over for analysis

TAVI.02 / TAVI.02-XL: inspection system with two glass tables and turn over station – the perfect solution for parts which must be analyzed from both sides

Our sales team will be happy to advise you - just ask us!

sales [at] nela.de (Contact us now)

CONTACT